Understanding Horizontal Chemical Process Pumps

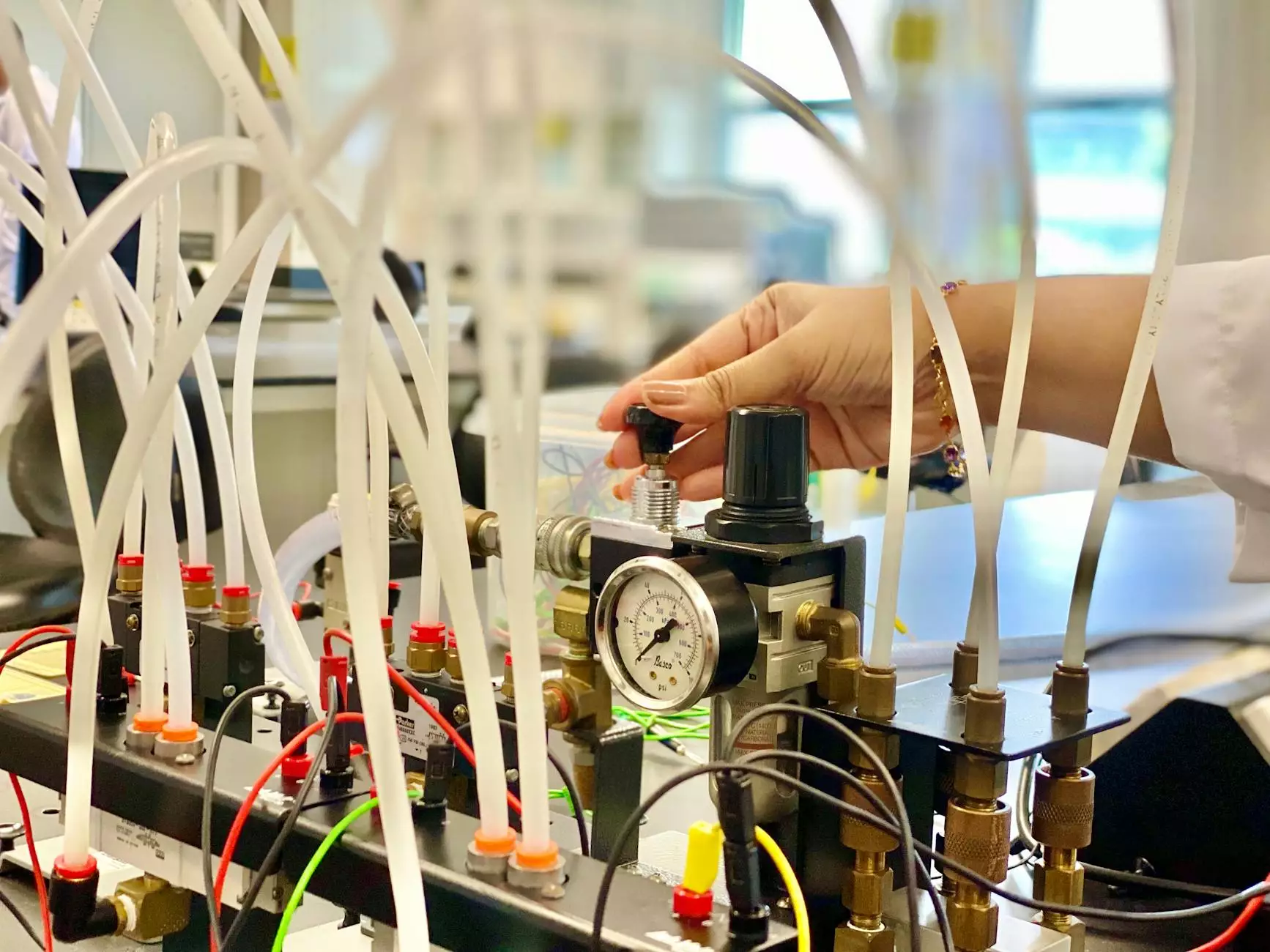

Manufacturing processes rely heavily on the efficient and reliable operation of a wide range of equipment, including horizontal chemical process pumps. These pumps play a critical role in various industries, especially in the safe and efficient transfer of chemicals and other liquids in manufacturing facilities.

The Importance of Horizontal Chemical Process Pumps

As a reputable manufacturer of chemical pumps, ZG Pump Valve understands the crucial role that horizontal chemical process pumps play in industrial processes. These pumps are specifically designed to handle corrosive and abrasive liquids, making them essential in industries such as chemical manufacturing, petrochemical production, and pharmaceuticals.

Benefits of Horizontal Chemical Process Pumps

Horizontal chemical process pumps offer several advantages that contribute to the smooth operation of manufacturing processes. These benefits include:

- Corrosion Resistance: Horizontal chemical process pumps are constructed with materials that offer exceptional corrosion resistance, ensuring longevity and reliable performance in harsh chemical environments.

- Efficient Fluid Transfer: These pumps are designed to efficiently move liquids over long distances, making them ideal for applications that require precise fluid transfer.

- Low Maintenance: Horizontal chemical process pumps are known for their low maintenance requirements, reducing downtime and ensuring continuous operation.

- Energy Efficiency: Modern horizontal chemical process pumps are designed to be energy-efficient, helping businesses reduce operating costs and improve overall sustainability.

Applications of Horizontal Chemical Process Pumps

The versatility of horizontal chemical process pumps makes them suitable for a wide range of applications in the manufacturing industry. Some common uses include:

- Chemical Processing: Horizontal chemical process pumps are widely used in chemical processing plants for the safe handling and transfer of various chemicals.

- Water Treatment: These pumps play a vital role in water treatment facilities for processes such as filtration, disinfection, and chemical dosing.

- Oil & Gas Industry: Horizontal chemical process pumps are essential in the oil and gas industry for applications such as crude oil transfer and refining processes.

- Pharmaceutical Manufacturing: These pumps are critical in pharmaceutical manufacturing facilities for the precise handling of pharmaceutical ingredients and formulations.

Choosing the Right Horizontal Chemical Process Pump

When selecting a horizontal chemical process pump for your manufacturing facility, it is essential to consider factors such as the type of liquids being handled, flow rate requirements, temperature and pressure conditions, as well as the overall reliability and efficiency of the pump.

Why Choose ZG Pump Valve for Your Chemical Pump Needs

As a leading manufacturer of chemical pumps, ZG Pump Valve offers a wide range of high-quality horizontal chemical process pumps that are designed to meet the stringent requirements of various industries. Our pumps are known for their exceptional performance, durability, and reliability, making them the ideal choice for critical industrial processes.

With a focus on innovation and customer satisfaction, ZG Pump Valve remains committed to providing cutting-edge solutions that enhance operational efficiency and productivity in manufacturing facilities.

Explore our range of horizontal chemical process pumps at ZG Pump Valve and discover the difference quality pumps can make in your manufacturing processes.